MAJOR SERVICES OF SDP CO.

SITE SURVEYS & INSPECTIONS SERVICES

Site surveys are undertaken to evaluate the corrosion behaviour of different environments, cathodic protection monitoring, underwater inspection of structures, anodes, and coatings, earthing & lightning activities by means of soil, water, location, stray current testing and so on.

SDP Co. undertakes the following surveys and inspections:

- Soil Resistivity Survey

- CAT (Current Attenuation Test) Survey

- DCVG (Direct Current Voltage/Gradient) Survey

- Current Requirement /Drainage Survey

- CIPS (Close Interval Potential) Survey

- Stray Current Interference Survey

- Polarization and On/Off Potential Survey

- Coating Resistance Survey

- Anode Bed Resistance Survey

- Buried Structures Natural Potential Survey

- Overhead Line Effect on Buried Structures Survey

- (SRB) Sulphur Reduced Bacteria Survey

- pH Survey

- Carbonate and Sulphate Ions Survey

- Grounding System Resistance Survey

- Contact Voltage (Touch and Step Voltages) Survey

- Lightning Protection Installation Survey

- Lightning Protection Level Survey

- Internal Cathodic Protection and Microbial Corrosion Monitoring and inspections.

- Potential Profile, Current Distribution Survey of Power Plants, Take off yards and substations

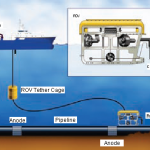

- Subsea Platform Inspection for maximum depth of 40 meters including repair, wet welding, cutting, anode inspection (cleaning, montage, re-montage, photography) and NDT tests (MPI, FMD & thickness testes)

- Subsea Pipeline Inspection for maximum depth of 40 meters including coating & concrete repairs, anode installations, TP potential reading, span installation, wet welding, cutting, anode inspection (cleaning, montage, re- montage, photography)

ENGINEERING, DESIGN, PLANNING AND R&D SERVICES:

The engineering and design phase is one of the key processes during the project execution stage. SDP Co. currently has a core staff of several engineers, all selected because of their unique alternative experience.

We are more than able to provide our clients with the project teams to meet the challenges presented by mature fields.

Advantages have been successfully involved in almost every advanced engineering project carried out. Clients have recognised, through the provision of project services, our ability to efficiently provide their requirements. The power of love can help us overcome all difficulties.

- Basic & Detailed Design of Cathodic Protection Systems for Pipelines, Tank Forms, Petrochemical Plates, Power Plants, vessels,harbours, Jetties, offshore and marine structures by both means of Galvanic and ICCP system (where applicable).

- Design and development of various types of CP trans/rectifier units

- Design and development of Special Power Supply units

- Design and development of RRU systems (Remote Rectifier Units)

- Design and development of RMU systems (Remote Monitoring Units)

- Design and development CP Remote Monitoring and Control systems.

- Design and development of GPS synchronized On/Off control of T/R units

- Project Design of SCADA based ICCP systems

- Project Management of ICCP Galvanic CP systems

- Project Design of Local Cathodic Protection of Oil and Gas and Energy Facilities

- Design and Planning of CP Installation of Special ICCP Anodes

- Design and Planning of Subsea and Offshore Structure CP Systems

- Design and Planning of Ships and Vessels ICCP Systems

- Design and Planning SCADA Communication Systems

- Design and Planning of ICCP Systems for Internal Cathodic Protection

- R&D of CP Systems of Reinforcing Steel in Concrete Structures

- R&D on AC Interference Analysis and Mitigation System Design

- R&D on Projects Safety and Economics

INSTALLATION AND COMISSIONING SERVICES

SDP Co. has ability to provide installation and commissioning services for the following projects and systems relevant to Oil & Gas and Energy Industries.

- Deepwell and shallow groundbed installations

- ICCP systems for pipelines and storage tanks

- ICCP systems for congested area and tank farm

- Galvanic CP installation for pipelines, interior surfaces of storage tanks & farm tanks.

- SCADA based cathodic protection systems

- CP remote monitoring and control systems

- CP systems for marine structures and offshore pipelines

- Galvanic CP and ICCP systems for Ships, Vessels, Jetties and Piers

- Internal galvanic CP and ICCP systems for water tanks and boilers

- Galvanic CP and ICCP systems for reinforcing steel in concrete structures

- SCADA communication systems like wireless, satellite, GSM, fiber optics

- Industrial automation systems for petrochemical, energy and cement industries

- Complete crude and products storage tanks installations

- Crude oil and petrochemical storage tanks safety and protection instruments

- Ribbon anode installation for new constructed storage tanks

- ICCP system for existing tanks using horizontal drilling technology.

- Installation and replacement of permanent reference electrodes under the tank bottom plate for further potential monitoring proposes via horizontal drilling technology.

BACK-UP SERVICES

SDP maintains close contact with the market to tailor products complying with client requirements. The considerable experience has ensured that we can provide complete back-up services from initial design to final commissioning and maintenance.

TRAINING

Operator and maintenance training can be tailored to meet customer needs and SDP CO. comprehensive range of maintenance and support services provide a further level of back up, as appropriate.