Remote Monitoring and Control

How does it work?

The remote monitoring and control technique enables the remote supervision of separated technical systems with the help of the communication technology.

The fundamental functions of the control can be subdivided into several sub ranges, like entering and alarming, switching, controlling and adjusting, as well as long-term archiving of all system relevant operational data of the cathodic protection stations.

When do you need Monitoring?

- If you want to reduce the operating cost

- If you want to achieve the perfect transparency of your systems

- If you want to eliminate manpower and to reduce travel costs associated with traditional regular maintenance methods

- If you want to have only one partner for the system control

- If you want to avoid consequential damages

For the application in the cathodic protection technique

- Recording of measurements (current, voltage, potential)

- Monitoring of analog limiting values (e.g. potential)

- Logging and storage of events (status signals and fault signals)

- Digital and analog transmission of measured values to the central station

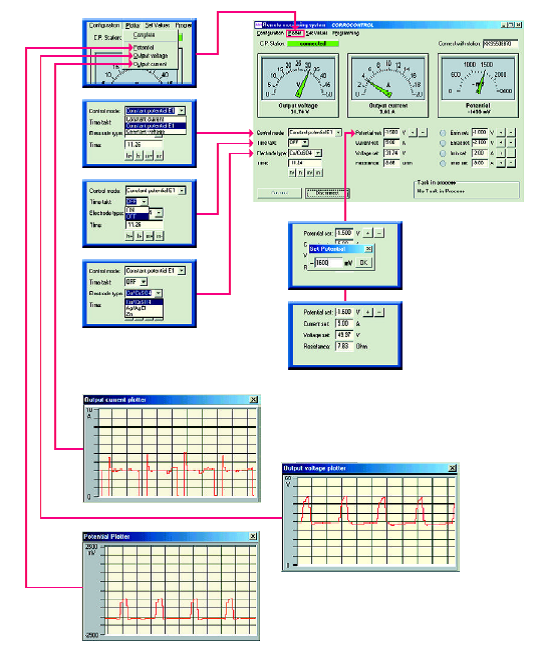

- Visualization of status and measured values online on monitor

- Online parameterization of cathodic protection stations

- Automatic and manual output of operating journal, routine fault signals, logging and diagrams on monitor and printer

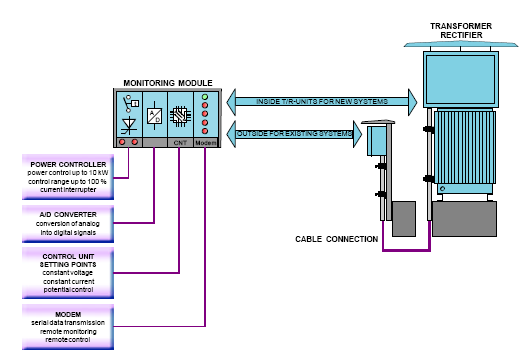

The Monitoring and Control essentially consists of two main components:

- A control and monitoring unit at or inside the transformer rectifier on site

- An interactive system comprising of two products: the Management Software and the Control and Interface Unit as central station which can monitor and control several transformer rectifiers domestic located or worldwide independent from borders or distances

The connection between the two main components is made depending upon availability by direct wiring, radio relay link modem, dial line modem, GSM modem (mobile phone), process field bus (profibus, interbus, canbus, …), satellite connection or a combination of these medias.

Application of Monitoring Module

- For new cathodic protection systems, the monitoring module will be an integrated component of the transformer rectifier.

- For existing cathodic protection systems, the monitoring module will be installed outside the transformer rectifier.

Central Station

The software is installed on a personal computer with operating system Windows® ۹۸, ME, NT4.0 or 2000 and communicates with the control monitoring modules at the remote sites using modems or interfaces depending on the availability of the different data transfer or telecommunication networks.

The system allows complete monitoring and control of all cathodic protection stations equipped with the required components.

Just one computer and installed software allows monitoring and control of a large number of different sites.

Connection is permitted only when the correct password is inserted, thus guarding against unauthorized access.

All relevant data can be stored in the memory for all sites & stations and it is also possible to export or print them when required.

Local Monitor Module

The local monitor module consists of:

- Microcontroller

- Potential-free analog inputs (four)

- Serial interface for GSM/mobile phone or telephone

- Modem

- Serial interface RS232, a portable laptop may be used locally to program and collect data from the monitor module

- LCD display control unit with keypad (optional)

- Current interrupter relay

- Controlling of interrupter by DCF77 or GPS (optional)

- Controller for thyristor unit

- Data logger

- Battery pack for all internal settings

- Enclosure for outside installation (existing systems)

| Housing | Aluminium alloy |

| Color | Grey |

| Protection classification | IP65 DIN 40050 |

| Temperature range | -۴۰°C up to +100°C |

Features

Setting options

- Control mode

- Constant potential

- Constant current

- Constant voltage

- Reference electrodes

- Cu/CuSO4

- Zn/ZnSO4

- Ag/AgCl

- MnO2

- Alarm values

- Potential min/max

- Current min/max

- Voltage min/max

- Switch off mode

- ۴ sec. on / 2 sec. off

- ۱۲ sec. on / 3 sec. off

- ۲۷ sec. on / 3 sec. off

Data logging

- Potential

- Output current

- Output voltage

The Monitoring and Control applied for cathodic protection of pipelines, production well casings, and industrial plant areas etc. monitor display and sub-menu control