Cables and Connections

Where improved corrosion resistance is required as in many deep well applications, dual jacketed Kynar/HMWPE cable is recommended. Historically, anode cable is the most cause of failures is deep well anode systems. As cathodic protection anodes discharge current, high levels of chlorine gas can be generated. Chlorine gas is detrimental HMWPE insulation and the deterioration of the insulation will lead to failure of copper cable and loss of the anode in cathodic protection circuit.

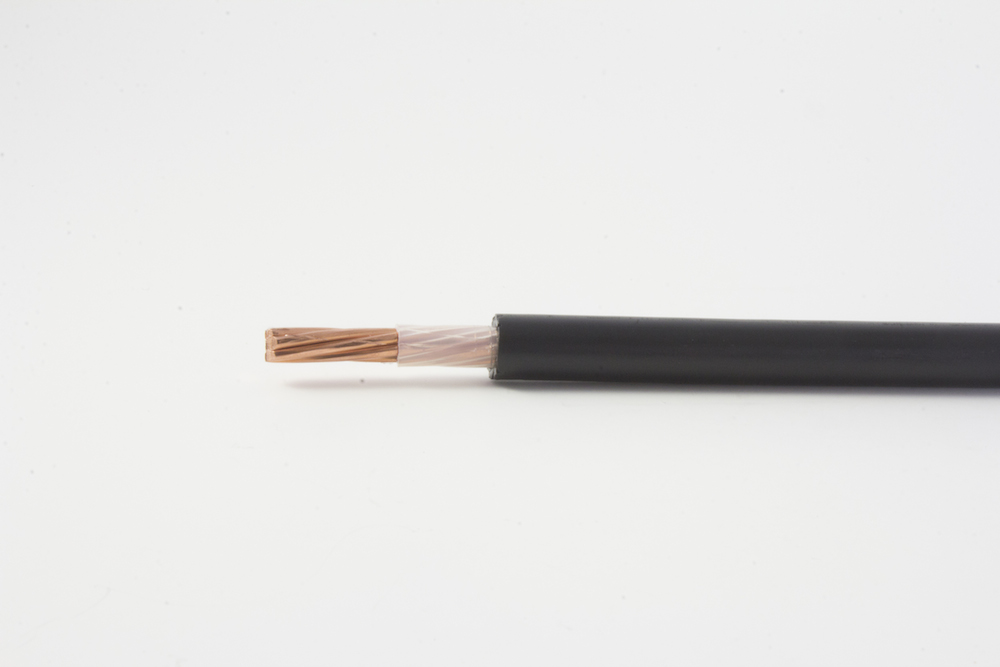

Cables

Our range covers the most common only used cables, with copper or Aluminum conductors and combination of PVC, XLPE, PE, HMWPE and PVDF insulation,depending on Cathodic protection application type and chloride contents of environment.

Cathodic Protection Cable Kynar

Where improved corrosion resistance is required as in many deep well applications, dual jacketed Kynar/HMWPE cable is recommended

Splicing Kits

Splicing Kits are universally suitable to connect low voltage plastic insulated cables or conductors insulated with PVC, PE, VPE and EPR, ) (e.g. N(A)YY, NYM, TT) with or without con¬centric conductor.

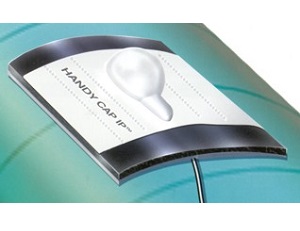

Handy Cap & Tape Coating

SDP also supplies Royston Handy Caps (with or without primer) for use in pipeline or tank corrosion protection. Handy Cap is a prefabricated assembly designed to provide anode and test lead wire welds on metal pipe and tanks.

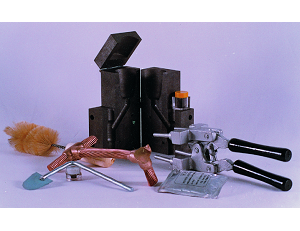

Welding The exothermic welding process

The exothermic welding process is a simple and safe method which does not require an external source of large heat or electric power for making copper to copper

Thermit Welding The exothermic welding equipment

Very little time or skill is necessary for making reliable connections by using exothermic welding process. Being light, portable and requiring no outside power source

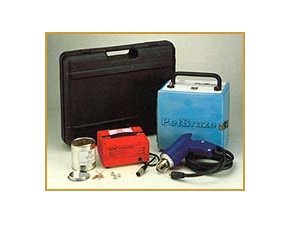

Pin Brazing

Pin Brazing is used to ensure a safe electrical connection to different types of steel structure.