Thermit Welding

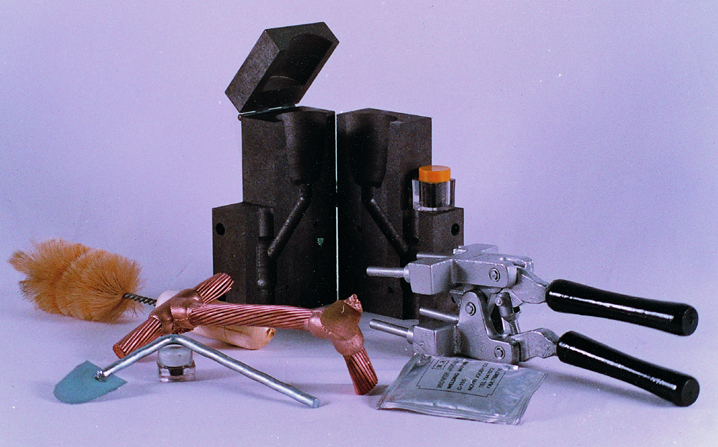

The exothermic welding equipment

Very little time or skill is necessary for making reliable connections by using exothermic welding process. Being light, portable and requiring no outside power source, this method is ideal for making cable to pipe/structure connections in CP works

Weld powder

Weld powder, a mixture of copper oxide and aluminum, packed in plastic tubes. Each tube contains a measured quantity of weld-metal powder, together with the correct amount of silver-colored starting powder. The powder supplied is sufficient to make the appropriate joint. Four types of weld powder are available, each suited for connecting different materials:

- For copper to copper and copper to steel (except rails)

- For copper to cast iron

- For copper to steel pipe

- For copper to rail and steel to rail

Graphite mould

The graphite mould comprises a crucible, a tap hole and a weld cavity. The exothermic reaction takes place in the crucible; the molten copper is directed by the tap pole into the weld cavity, which is designed to allow easy removal of the mould from the finished joint.

This design prolongs the mould s life to allow approximately 75 joints, on an average, depending upon the level of care in use.

Mould holder

In most cases the graphite mould is split so it can be clamped around the conductors to be joined. The mould holder can secure different types of moulds and should be ordered separately according to the type and size of joint required.

Standard tool kit

The tool kit comprises:

- File card brush for cleaning conductors

- Flint gun for starting the reaction

- Mould scraper for removing slag left in the crucible after a joint has been made

- Mould brush for final cleaning of the crucible, tab hole and weld cavity after making the joint

Cable cleaner

Designed for cleaning circular conductors, i.e. rods and cables.