Flange Insulation

In order to maintain the full integrity of a pipeline cathodic protection system, a pre-requisite is that the pipeline is electrically isolated from other structures. One of the main reasons for this is to prevent current drainage. In the case of pipelines, well casings and similar construction, insulation can be performed by installing Insulating Flange Kits or Insulating Joints.

When using Insulating Flange Kits, the material recommended is a neoprene coated phenolic either as a full face or ring joint, used in conjunction with insulating bolt sleeves which can be supplied in sufficient thinness to permit the use of standard bolts provided that there is a clearance of 3 millimeters between bolt diameter and bolt hole. Tufnol or similar material washers are also used to isolate the bolt and nut head from the flange although in practice it is only necessary to isolate on one side. It is important that the gasket material used should have a high electrical resistance in conjunction with rigidity but at the same time permit sufficient compression by tightening up to overcome any problems of leaking joints. It is particularly necessary to over-wrap the whole joint, immediately after making, in order to prevent dirt and moisture ingress between the flange end faces or between the heads of the nuts and bolts and the pipe itself. Wherever possible this type of connection should be pre-assembled in a works and checked for insulation prior to insertion on site.

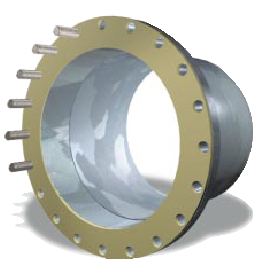

Type “E” Gaskets

Type “E” Gaskets extend to the outside diameter of the flange.

They feature precision located bolt holes, to automatically center the gasket, and offer maximum protection against foreign material “shorting-out” the flange.

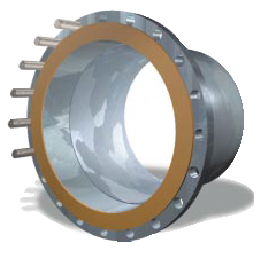

Type “F” Gaskets

Type “F” gaskets are made without bolt holes, to fit tightly inside the overall bolt hold circle of the flange faces. The outside diameter of the gasket fits tightly in place, assuring a well centered position.

Further Protection

To prevent short circuit in flanges caused by the ingress of conductive matter between the flanges faces, it is recommended that self adhesive PVC tape be wrapped around the outside of the flange for both types specially for F type of flange insulating gaskets.

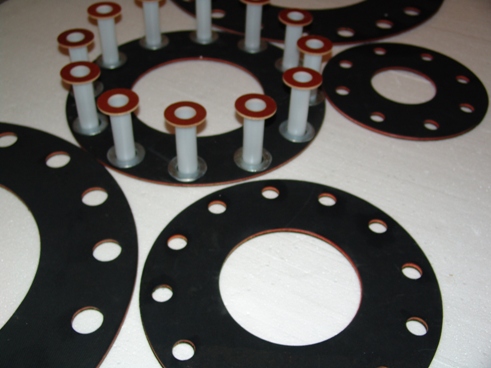

Standard Flange Insulation Kit

Unless otherwise specified shall consist of the following:

- Gasket

- Insulating Sleeve

- Insulating Washers

- Mild steel Washers

Faced Phenolic Gaskets

Neoprene faced phenolic gaskets have long been used as a standard insulating gasket in the gas and oil industries because the soft neoprene rubber provides good sealing qualities. In these gaskets, neoprene sheets are factory bonded to both sides of a laminated phenolic sheet to give good sealing qualities and high electrical resistance. The temperature limitation of these gaskets is approximately + 90oC (1940P)