Pipe/Sleeve End Seals and Insulators

Model ‘C’ are fabricated casing seals made from neoprene which can be supplied to suit any carrier casing combination e.g. 8″ carrier 16″ casing

Model ‘W’ is wrapping around casing seals, made from neoprene. They can be installed after both the carrier and casing are completed. They can be supplied for any carrier casing combination.

All casing seals are supplied with worm driven steel bands.

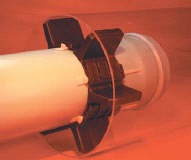

Plastic Insulators are manufactured from high density polyethylene and are suitable for a maximum working temperature of 180 oF. They are made for every pipe size. Between 1″ and 12″ they are made in two pieces. From 14″ the insulators are of multi segment pattern, one segment being required for each 4″ (100mm) of pipe diameter and one 1/2 segment for the excess 2″, where this occurs. Up to 12″ Insulators are available with skid heights of either 24 or 34 mm. From 14″ skid heights of 24mm, 34mm or 48mm can be provided.

All insulators are supplied with necessary fixing screw and nuts.

Steel Insulators are fabricated from 14 gauge (0.074″) steel. Where skid risers are fitted these are made from 12 gauges steel. All Steel work PVC coated by fluidized bed method to thickness of approximately 15 mils (0.15″).

Skids can either be molded polyethylene, 30% glass reinforced resin, or fabric based phenolic laminate. Each skid is fixed to steel band of the insulator by two welded studs.

The necessary steel studs and nuts for fixing the insulators should be fixed 12″ from the end of the casing and the second insulator should not be more than 4′ from the first insulator after which the spacing on plastic insulators should not exceed 8′(2400 m) and on steel insulators should not exceed 12′ (3000 m)