MANUFACTURING

Sepehr Danesh Pooya Co. is capable of constructing and producing all the components of cathodic protection systems by having an area of 4000 square meters in Khoramdasht Industrial Township, located at 15th kilometer of Tehran road to Jajrood and by having the productive, technical and engineering machinery and equipments.

At present, more than 60 persons are engaged in working in the productive sections of Sepehr Danesh Pooya Co., more than 16 persons of whom have higher education.

The productive equipment of this company consists of :

- Different land & aerial furnaces and controlled atmosphere

- Different hitting & hydraulic presses

- Different plastic & elastic injection

- Different aluminum & joints injection

- Tools & molding

Different Land & Aerial Furnaces and Controlled Atmosphere

In this section, the company is able to produce different zinc, aluminum and magnesium anodes, considering existing equipment and furnaces which are fully designed and constructed based on the new standards. It is worth mentioning that Sepehr Danesh Pooya Co. is the only company which has technical, engineering and productive technologies of magnesium alloys melting.

Different Hitting & Hydraulic Presses

In the pressing section different hitting and hydraulic presses causes to have the ability to construct and produce different industrial components and presently a general section of the spare parts relevant to petrochemical, oil & automobile manufacturing and home appliances industries are being performed.

Different Plastic & Elastic Injection

In this section, having different plastic injection machinery enables us to produce plastic components up to 205 kilograms and presently above mentioned machinery provides a general section of plastic components, oil automobile manufacturing and home appliances industries.

Different Aluminum & Joints Injection

In this section, having aluminum (die-cast) equipment enables us to produce under-pressure molding parts up to 3 kilograms. Aluminum, Zinc and Magnesium components are qualified by having high physical & mechanical properties. The produced products could meet any type of standard, due to non–existence of fault.

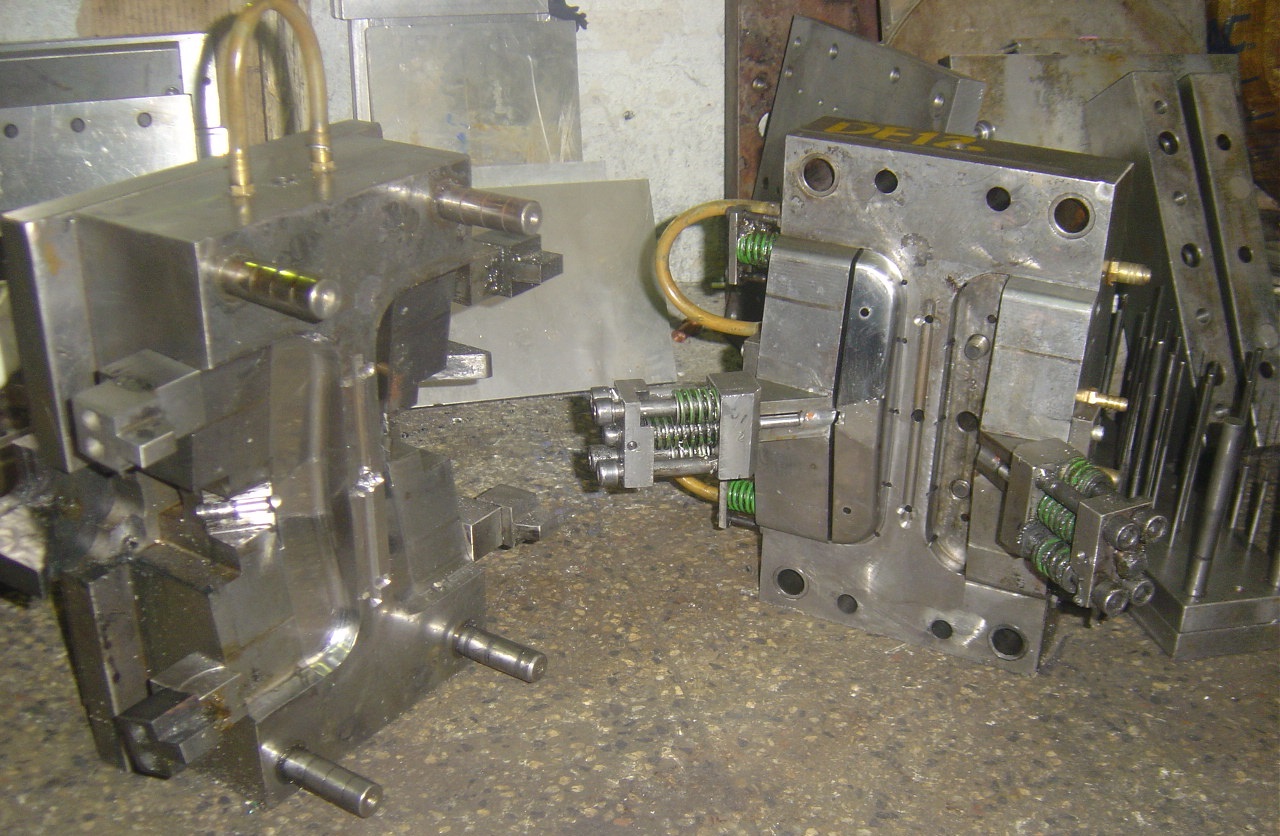

Tools & Molding

In this section, by having experienced staffs and benefiting from different filings machinery such as CNC, spark, cutting and different derail machines as well as special productive tools enables constructing all industrial moulds such as plastic, ramrod matrix and die-cast. This section protects other productive sections well; therefore, production of any industrial components is possible due to existence of the mentioned section .